India’s automotive ecosystem is operating in an environment where a significant portion of aftermarket components circulating under branded names may not be genuine. Yet most manufacturers and suppliers still lack a reliable way to determine a fundamental reality:

Which parts in circulation are authentic, and which only appear to be?

Estimates referenced by the Automotive Component Manufacturers Association of India (ACMA) indicate that 30–40% of the automotive aftermarket may consist of spurious or counterfeit components. This reflects not an isolated issue, but a systemic loss of visibility across the aftermarket.

In this context, automobile counterfeiting is no longer limited to informal markets or low-quality spares. It has evolved into a widespread operational challenge affecting safety, reliability, and trust across the automotive value chain.

Invisible Substitution: How Counterfeit Parts Enter Legitimate Channels

The assumption that counterfeit parts are confined to roadside sellers is increasingly inaccurate. Today’s counterfeit components are often visually indistinguishable from genuine parts and are distributed through semi-authorized or even authorized service networks.

These parts may function normally at first and fail only after prolonged use. When such failures occur, the source is rarely obvious. Without product-level identification, it becomes extremely difficult to determine whether a failure originated from a genuine component or a counterfeit substitute.

As a result, accountability frequently falls on the brand, even when the part involved was never manufactured or supplied by the original company. This makes counterfeiting not just a quality issue, but a traceability and control issue.

Why the Automotive Aftermarket Is Especially Vulnerable

The aftermarket differs significantly from OEM manufacturing environments. It involves multiple intermediaries, fragmented distribution networks, informal retail layers, and inconsistent documentation practices.

Counterfeiters exploit this fragmentation. Packaging, labels, and branding are replicated with high accuracy, making visual checks unreliable. Without identity embedded directly into the component, it is difficult to track genuine products once they leave controlled manufacturing and distribution environments.

This lack of visibility prevents early detection. Counterfeit concentrations often become apparent only after failures, complaints, or enforcement actions—by which time the damage has already occurred.

When Component Failure Becomes a Safety Risk

Counterfeit automotive components bypass material standards, durability testing, and certification requirements. Their performance is inconsistent, and their failure modes are unpredictable.

Such failures often occur under stress conditions—during emergency braking, sustained high-speed operation, or sudden load changes—where component reliability is critical. Parts that appear functional under normal driving conditions may fail abruptly when exposed to real-world extremes.

In practice, public perception rarely distinguishes between counterfeit-induced failures and genuine manufacturing defects. As a result, manufacturers, service networks, and regulators often face scrutiny regardless of whether the failed component was authentic or counterfeit.

The Economic Impact Extends Beyond Lost Sales

Counterfeiting is often described as a loss of revenue from diverted sales. In reality, the economic impact is broader and cumulative.

Warranty claims rise when counterfeit failures are misattributed to genuine parts. Investigations, audits, and legal actions consume resources without necessarily improving future prevention. Distributors and workshops face reputational risk when counterfeit components unknowingly pass through their channels.

Industry estimates referenced by FICCI CASCADE suggest that counterfeit auto parts contribute to approximately ₹2,200 crore in annual government revenue loss, reducing resources available for enforcement and safety initiatives.

Why Existing Regulations Have Limited Effect

India has legal frameworks covering trademarks, consumer protection, and quality standards. However, these frameworks largely address counterfeiting after it has occurred.

There is no mandatory requirement for product-level traceability of automotive components in the aftermarket. Enforcement actions are typically complaint-driven or incident-based, rather than preventive.

Once counterfeit parts are widely distributed, tracing their origin becomes extremely difficult. This reactive approach limits the effectiveness of regulation in complex, high-volume aftermarket environments.

Limitations of Traditional Anti-Counterfeiting Measures

Holograms, QR codes, serial numbers, and packaging-based identifiers have been widely adopted. However, counterfeiters now replicate these features with increasing sophistication.

Because these measures are external and visible, they are vulnerable to copying and reuse. More importantly, they do not generate data about product movement, repeat violations, or regional patterns.

As a result, they offer limited long-term control and little insight into how counterfeit networks operate.

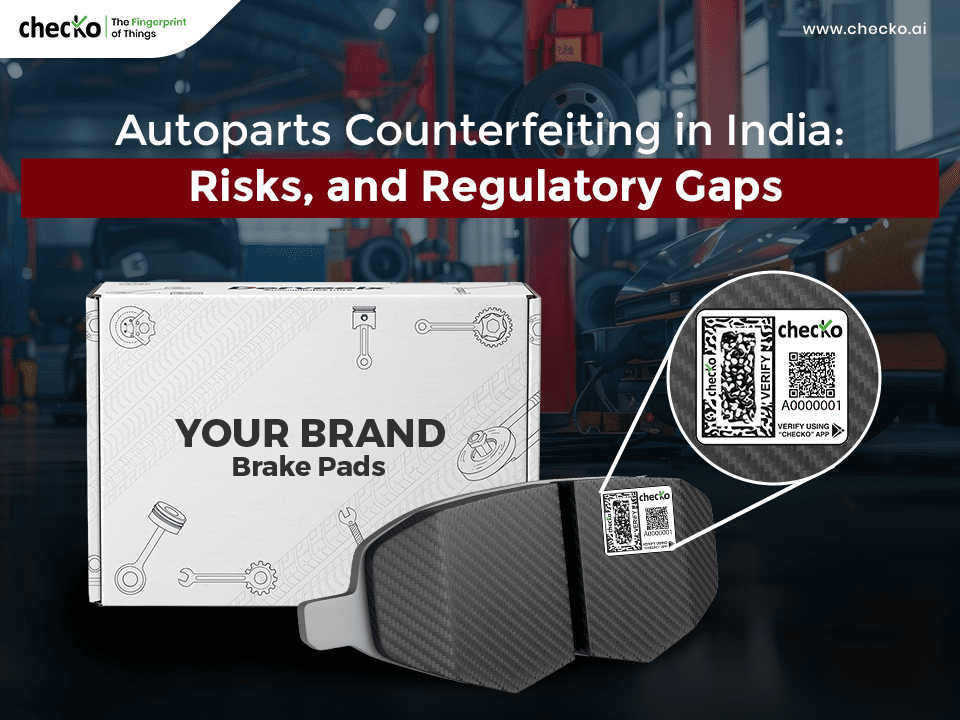

A Shift Toward Product-Native Authentication: The Role of Checko

Checko addresses automobile counterfeiting by embedding authentication directly into the automotive component itself.

Checko applies a copy-proof 3D puf label onto the product, creating a secure, non-replicable identity that cannot be duplicated, removed, or reused without detection. Because the identity is product-native, authentication remains possible even after the packaging is discarded.

Each verification generates contextual information such as location and time, creating visibility across manufacturing, distribution, retail, and service stages. This enables earlier detection of counterfeit activity and supports a shift from reactive enforcement to preventive control.

Time to Transition: From Detection to Prevention

Automobile counterfeiting in India has evolved into a complex challenge rooted in limited visibility and fragmented aftermarket structures. ACMA-referenced estimates highlight the scale of counterfeit penetration, while accident and revenue-loss data demonstrate the real-world impact.

Addressing this issue requires moving beyond surface-level security features toward product-level identity and continuous visibility. Technology-driven approaches that embed authentication into the component itself offer a practical path toward improved safety, accountability, and trust across the automotive ecosystem.

In an industry where reliability and safety are critical, preventing counterfeit infiltration is not optional—it is essential